The very process of manufacture for ZIYANG is constituting the innovation of two axes; sustainability and actually eco-friendly. There is a continuous focus on environment-friendly yoga apparel over the complete cycle of design and manufacture. Thus, all our apprehensive ways of all apparel are top-end and trendy while being absolutely eco-friendly. This is a concise look into the process whereby all our eco-yoga wear-from cradle to grave-is produced.

Step 1: Sustainable Raw Material Selection

Eco-friendly best start by conscious yoga-apparel manufacture even at the point where raw materials are sourced for sustainability. ZIYANG follows closely the all-encompassing attention bestowed on fabrics with the least possible environment impact without compromise on comfort and performance.

Organic Cotton- No synthetic pesticides and fertilizers are engaged in these cultivation practices so that organic cotton nourishes a healthy soil and a decreased run-off of chemicals. Bamboo Fiber- It does not emit volatile chemicals and also has a very low requirement for water during its agriculture, in addition to its natural biodegradation, antifungal, and antibacterial properties. Recycled Polyester (RPET): Calling RPET after recycled plastic bottles, this minimizes the production of plastic wastes and is enough durable to maintain adequate performance.

Step 2: Environmentally Friendly Manufacturing Process

After selecting fabrics, ZIYANG applies all the green manufacturing processes through which energy consumption and environmental negativity are minimized at the production level.

Ecological Dyes: Non-toxic chemicals and not harm the ecosystem; power to get filtered in no time from this ecosystem without harming the water sources.

Water Saving: Reduced discharge from these units by adopting newer dyeing and washing technologies with a minimum amount wasted use of water.

Energy-Efficient Equipment: Therefore utilizing machines that sew its yoga apparel with maximum efficiencies of energy are complete, thus finishing the process with a substantially lesser carbon footprint.

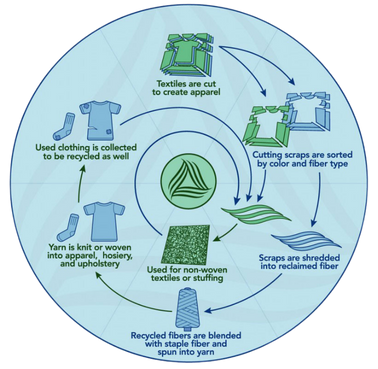

Step 3: Recycling and Reusing Materials

ZIYANG makes an effort to reuse and recycle materials wherever possible to trying to make a whole cycle of destruction. Under this, we aim to Reduce, Reuse, and Recycle: thus contributing to the circular economy.

Fabric Waste Recycling: Fabric cuttings and overproductions are collected. Avoidance of waste, forming into new objects later on.

Collection of Old Garments: We coordinate with customers in collection of old yoga wear to be turned into new garments or recycled.

Upcycling: These are linked with recycling companies for converting textile waste into fibers of high quality for future production.

Step 4: Eco-Friendly Packaging

Packagings also have a significant impact in any sense, be it material or energy. The signature sustainable packaging by ZIYANG provides solutions that help cut down waste and would not be friendly toward plastics.

Biodegradable and Recyclable Materials: All packing materials are biodegradable or recyclable and minimal impacts to the environment.

Minimalism: Design minimal with materials just sufficient to protect garments against any kind of damage while on their journey, thus minimizing all possible excess waste.

Eco-Friendly Inks: All branding and labels are printed in water-based non-toxic inks to improve our environmental footprint.

Step 5: Assurance for Quality Control

Whenever ZIYANG produces something, we nurture the value that it has to be of quality standards and provide the opposite to the environment.

GOTS Certification: ZIYANG has its organic cotton fabrics certificated under the Global Organic Textile Standard (GOTS), thus offering evidence that the fabric meets stringent environmental and social criteria.

OEKO-TEX Certification: All products are tested against harmful substances. This means that our hugs are safe not only for consumers but also for the planet.

ISO 14001 Compliant: Process of manufacturing is compliant with ISO 14001, which is an international standard for environmental management.

6. Step 6: Entire Production Process

Everything we do at ZIYANG is built around being eco-friendly, functional, and, of course-most of all-really comfortable at sustainable yoga wear.

Spinning: Spinning the best fibers available worldwide produces robust and consistent yarn using energy-efficient processes such as spinning.

Weaving/Knitting: Manufacturing our fabrics that so carefully balance comfort and durability through the latest technologies that aim for minimal material waste.

Dyed: Bright colors are dyed in methods that polluted the least water and are reasonably versed in toxic chemical ramifications.

Finishing:preparation of the fabric for durability and function while conserving electricity and water.

Cutting and sewing:cutting for least waste while sewing in sustainable threads.

Quality Check: At every single piece of apparel, an extensive series quality checks have been up

Post time: Feb-20-2025