Garment pattern making, also known as garment structural design, is the process of transforming creative clothing design drawings into actual usable samples. Pattern making is an important part of clothing production, which is directly related to the pattern and quality of clothing. This process not only involves technical pattern making, but also includes working closely with designers to ensure that the final product meets the design concept and style. The following is the general process for pattern making clothes:

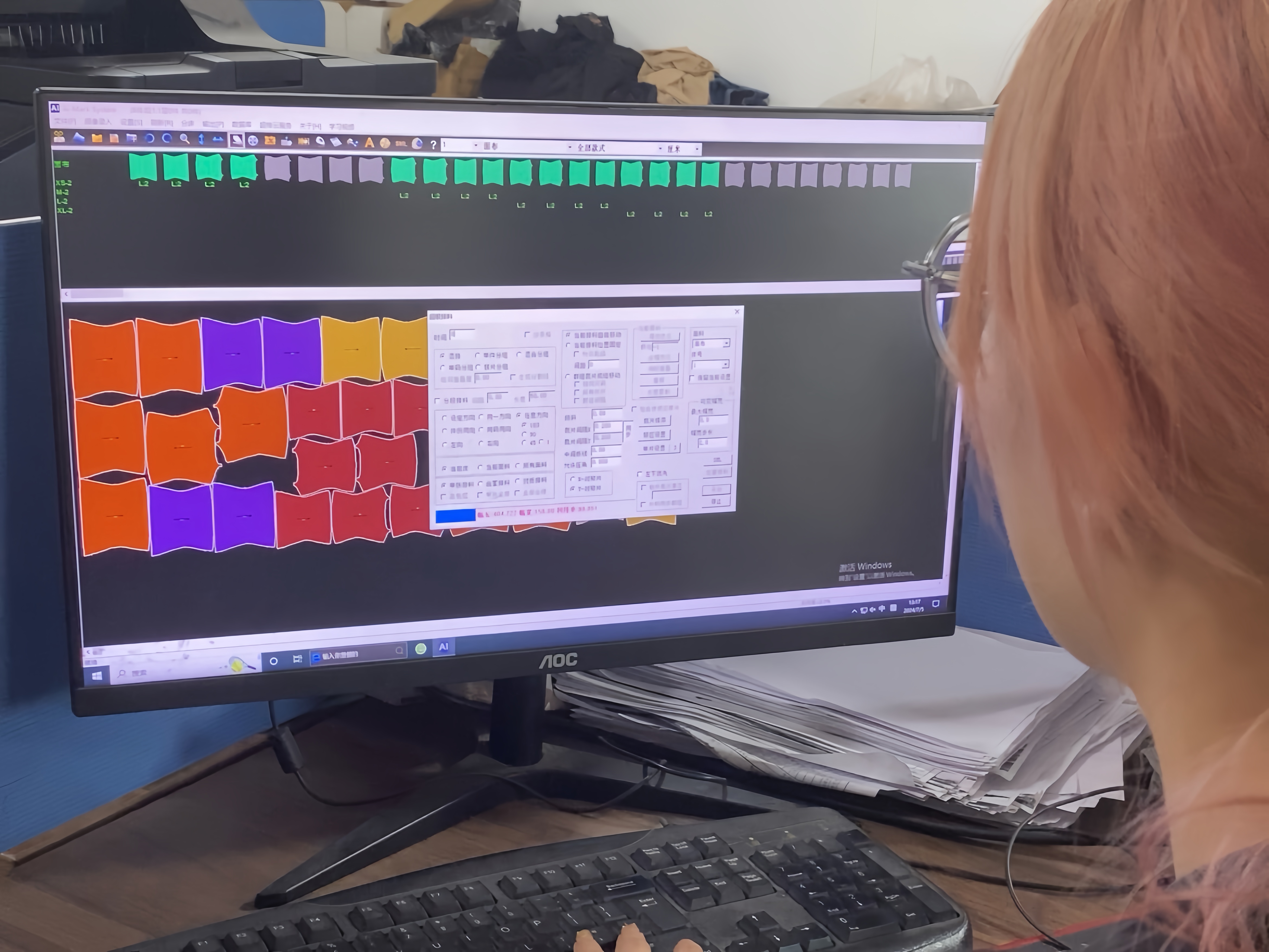

1. Draw drawings on the computer according to the design drawings.

According to the design drawings, analyze the design drawings in detail to understand the style, size and process requirements of the clothing. Converting design drawings into paper patterns on the computer is a process of converting design drawings and paper patterns into digital numbers, including the dimensions, curves and proportions of each part. Paper pattern is the template for clothing production, which directly affects the style and fit of clothing. Paper pattern making requires precise dimensions and proportions, and pattern making requires a high degree of patience and meticulousness.

2.Use a machine to cut the kraft paper to produce a paper pattern:

including the front piece, back piece, sleeve piece and other parts.

3.Draw the pattern: Use pattern paper to cut the fabric. In this step, you will first use scissors to cut out a square shape from a roll of cloth, and then use a machine to carefully cut the square cloth according to the paper pattern, and check whether each part matches to ensure the accuracy of the pattern.

4.Make sample clothes: Make sample clothes according to the pattern, try them on and make adjustments to ensure the fit and appearance of the garment.

Before production, check the fabric characteristics with the sample designer: such as positioning strips, positioning flowers, hair direction, fabric texture, etc., and communicate with the sample before cutting as required. Before making the sample garment, it is necessary to glue the lining, pull the welts, and the seaming parts to be indented and opened to further communicate with the sample garment. Semi-finished product inspection. Special parts and parts with special processing are studied and reviewed with the designer and sampler to adjust to the best effect.

5.Finally,measure the dimensions of the sample,try it on and correct it. After the sample is completed, it needs to be tried on. Trying on is an important part of testing the fit and fit of clothing, as well as a time to identify problems and make corrections. Based on the results of the try-on, the pattern maker needs to make corrections to the pattern to ensure the style and quality of the garment.

Things to note when making yoga clothes

When making yoga clothing, there are several key craftsmanship considerations to consider to ensure the garment is comfortable, functional, and stylish:

Fabric selection: The fabric of yoga clothes should give priority to comfort and elasticity. Common fabrics include nylon and spandex, which provide good stretch and recovery rates.

Seamless knitting technology: With the development of technology, seamless knitting technology is becoming more and more popular. This technology provides greater comfort and a better fit by avoiding seams that bind the elasticity of the knitwear. Seamless knitted products combine comfort, consideration, fashion and functionality, making them a favorite among yoga and fitness consumers.

Design elements: The design of yoga clothes should focus on comfort and functionality, while considering diverse design elements to attract consumers. This includes exquisite hollows and textures, jacquard patterns, and lines specially designed to lift the hips. These designs can not only enhance the visual appeal of the clothing, but also adapt to different sports environments.

Color and style: The color and style of yoga clothing should be chosen taking into account the nature of the exercise and the user's comfort. It is recommended to choose simpler colors and styles to avoid distracting attention during exercise. At the same time, according to the season and sports needs, choose suitable trousers, shorts, tops, etc. to ensure that the clothing can adapt to different sports intensities and environments.

Quality and certification: Manufacturers should ensure product quality and pass relevant quality and safety certifications, such as Walmart factory inspection, BSCI factory inspection, Rheinland certification, ISO9001 certification, etc., to ensure product safety and reliability.

There are detailed videos of the sample production process, please see our official Facebook and Instagram accounts.

Facebook:https://www.facebook.com/reel/1527392074518803

Instagram:https://www.instagram.com/p/C9Xi02Atj2j/

Post time: Jul-10-2024