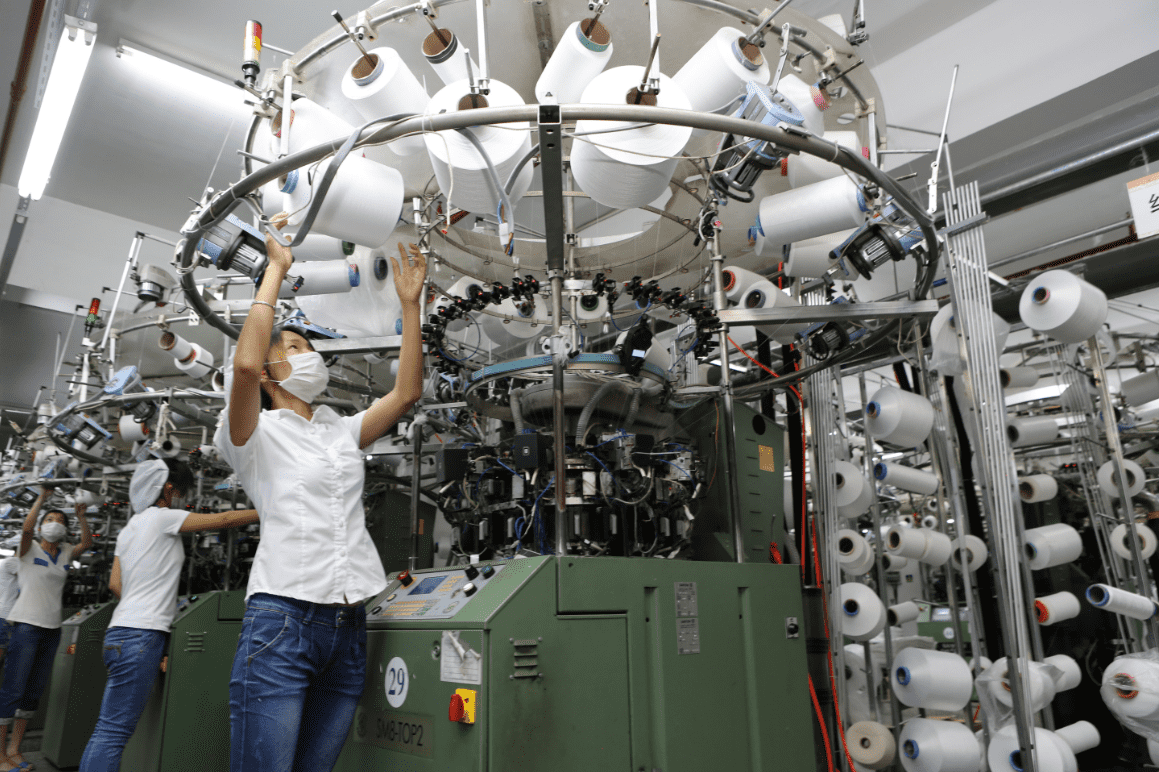

In a conversation between the Sales Manager of Seamless Division and an expert , it is revealed that the sportswear is produced using seamless machines from the TOP series, which utilizes the innovative iPolaris pattern-making software. The seamless machine in the TOP series functions as a 3D printer for garments. Once the designer completes the design, the pattern maker creates the garment program within the professional software iPOLARIS. This program is then imported into the machine, which weaves the designer's pattern. The garments produced by the TOP series have superior comfort and flexibility. By adjusting the tension at specific positions in the program, the clothing can better conform to the body's curves, providing greater comfort and emphasizing the wearer's figure. The seamless production process also offers support to specific muscle areas, providing protection without excessive compression or restriction, making it suitable for yoga wear, functional sportswear, and underwear.

The impact of seamless technology on the wearing experience of clothing is significant. Unlike garments with seams that can cause discomfort due to friction with the skin, seamless garments have no visible stitching lines and can wrap around the wearer's body like a "second skin," enhancing comfort.

Seamless technology also offers more creative freedom for fashion designers. It allows for the weaving of special fabric structures and patterns directly onto the garments. For example, a collaboration resulted in a Chinese-inspired garment with a woven dragon motif and surrounding cloud patterns, which was achieved through seamless technology.

Seamless technology has achieved notable success and is frequently seen in international sports events. For instance, some of the inner skiwear worn by athletes in the recent Winter Olympics was produced using seamless machines. The seamless production of sportswear allows athletes to enjoy enhanced breathability and comfort without compromising support and fit.

Post time: Feb-21-2024