Sample Development Process

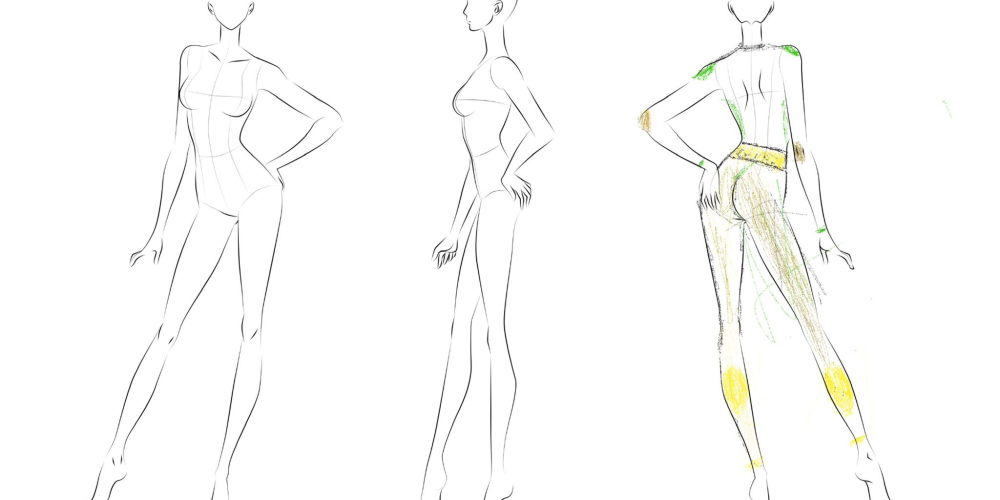

If you want to start a fashion brand rather than simply buy and sell products, then you're going to need to make something yourself. This means you need to deal with the factory and go through a proofing process. Here, we will introduce you to the proofing process. You will clearly understand how a sample is made.Our sample production takes 7-15 days, this is our sample development process.

Before mass production, it is crucial for the factory to create samples and confirm them with the customer. This process not only helps ensure that the final product meets design specifications and customer expectations, but also reduces potential errors and waste during production.

How are samples made?

1.Draw drawings on the computer

According to the design drawings, analyze the design drawings in detail to understand the style, size and process requirements of the clothing. Converting design drawings into paper patterns on the computer is a process of converting design drawings and paper patterns into digital numbers, including the dimensions, curves and proportions of each part. Paper pattern is the template for clothing production, which directly affects the style and fit of clothing. Paper pattern making requires precise dimensions and proportions, and pattern making requires a high degree of patience and meticulousness.

2.pattern making

Utilize a cutting machine to accurately cut kraft paper, producing precise paper patterns for the garment. This process involves creating individual patterns for essential components such as the front piece, back piece, sleeve piece, and any additional parts needed for the design. Each pattern is carefully crafted to ensure accuracy in dimensions and shaping, which is crucial for achieving the desired fit and style of the final garment. The cutting machine enhances efficiency and consistency, allowing for multiple pieces to be cut simultaneously while minimizing material waste.

3.fabric cutting

Use pattern paper to cut the fabric. In this step, you will first use scissors to cut out a square shape from a roll of cloth. Next, use a cutting machine to carefully cut the square cloth according to the outlines of the paper pattern. During the cutting process, it is essential to check the fabric's direction and any markings to ensure the accuracy of the pattern. After cutting, check each fabric piece against the pattern to ensure consistency, which is very important for the subsequent assembly.

4.Make sample garments

Create sample garments based on the developed patterns, carefully selecting fabrics that align with the design intent. The construction of the sample involves sewing together the various components, such as the front, back, sleeves, and any additional details specified in the pattern. Once the sample is completed, it serves as a tangible representation of the design, allowing designers and stakeholders to visualize the final product and assess its overall aesthetic and functionality. This sample will be crucial for evaluating the garment's style before proceeding to the mass production phase.

5.Try it on and correct it

After the sample is completed, it needs to be tried on. Trying on is an important part of testing the fit of the clothing and identifying any issues. During the fitting, the overall appearance and the fit of each part of the garment can be evaluated. Based on the results of the try-on, the pattern maker needs to make adjustments to the pattern to ensure that the final garment meets the desired style and quality standards. This process is crucial for ensuring the garment's suitability and comfort.

Introduction video

Sample development process

Before mass production, creating and confirming samples is an important step that helps us ensure the final product meets customer expectations. This video will show you how samples are made.

Learn more about our services

We charge a $100 sample fee, which includes the cost of the samples, shipping, and any subsequent modification fees.The lead time for in-stock fabrics is 2 weeks.

Garment accessories are essential components in the world of fashion, serving both aesthetic and practical purposes

These items can transform a basic piece of clothing into a stylish and functional garment.